Пополнение счета БК «Мостбет»

Букмекерская контора «Мостбет» – крупный оператор по приему ставок. БК принимает игроков из разных стран и каждому предлагает индивидуальные условия игры согласно его местоположению. В данной статье разберем все методы пополнения счета Mostbet для украинского рынка игроков. Выберем самый универсальный и удобный способ для депозита.

Способы пополнения средств из БК «Мостбет»

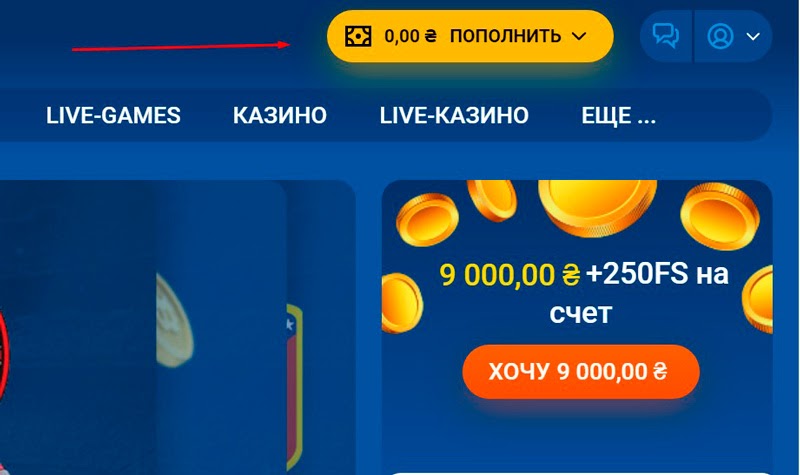

В «Мостбет» пополнить счет можно различными способами как с компьютера, так и с помощью мобильных приложений Мостбет. Метод пополнения зависит от того, в какой валюте был создан аккаунт в БК. Перейти к выбору можно с главной страницы официального сайта. Контора вывела прямую ссылку для депозита в правой верхней части экрана (см. скрин). Второй путь открывается через личный кабинет, раздел «Пополнить счет».

Кнопка для пополнения счета

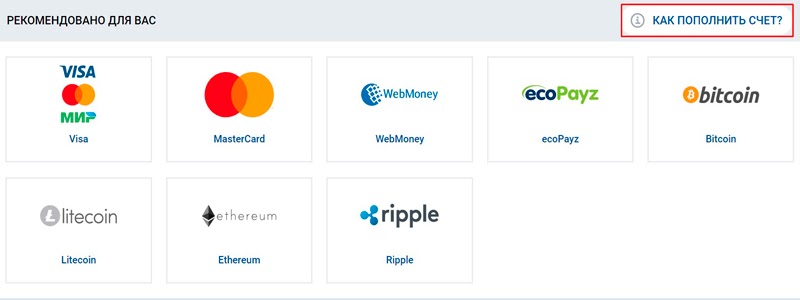

Система сама предложит все доступные методы, чтобы провести пополнение счета Mostbet. Чтобы получить полную информацию по каждому из способов, нажмите кнопку «Как пополнить счет?» в правом углу страницы. На скрине представлены все варианты депозита в украинской гривне.

Методы пополнения счета в Mostbet

Все методы делятся на три категории:

- Банковские карты;

- Электронные кошельки;

- Криптовалюта.

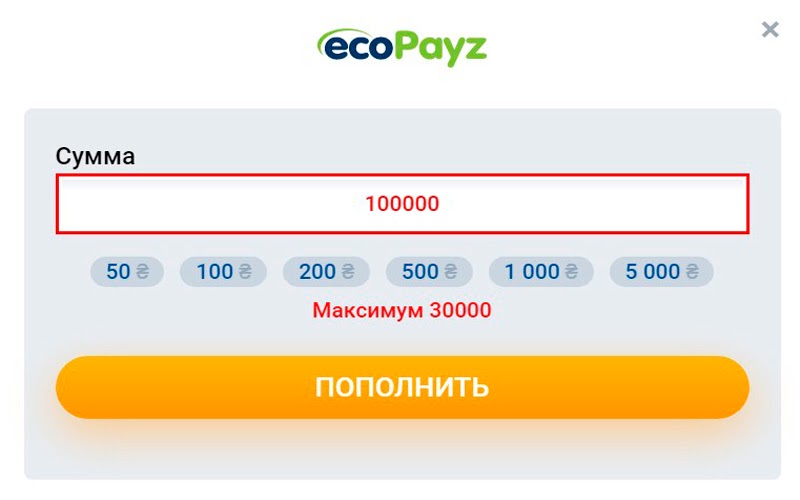

Минимальная сумма пополнения счета для любого метода — 50 гривен. Максимальный «порог» не указан, но чтобы проверить возможности каждого способа, достаточно ввести сумму в 100 000 и система сама покажет ограничение. На данный момент через одну транзакцию можно провести не более 30 000 гривен вне зависимости от способа депозита.

Максимальный лимит для пополнения

Подробный гайд по пополнению средств

Теперь разберем каждый способ по пополнению средств по отдельности. Некоторые методы имеют свои особенности.

Проверить наличие бонусов за пополнение в Мостбет — можно на нашем сайте

Карты Visa и MasterCard

Пополнить счет можно от 50 до 30 000 гривен за один раз. Достаточно ввести реквизиты карты и подтвердить действие в приложении банка. Деньги на счет поступают мгновенно.

Пополнение картой в Mostbet

Пополнение картой Visa и MasterCard проходит мгновенно. Букмекер никакой комиссии за депозит не взимает, но это может сделать банк.

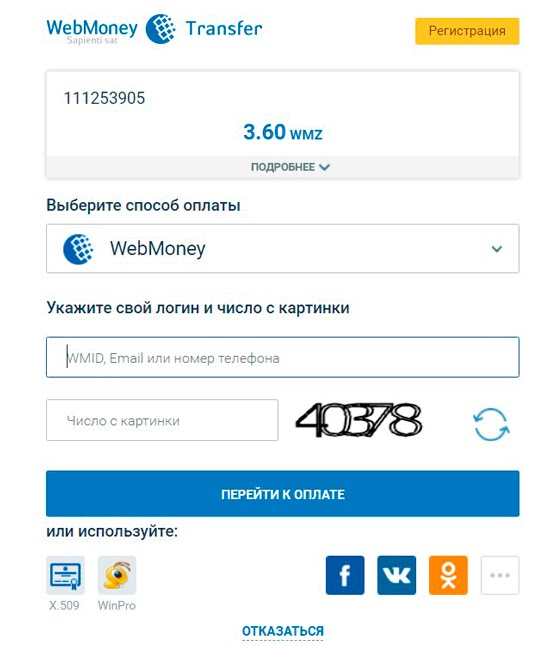

WebMoney

К пополнению через электронный кошелек WebMoney игрокам стоит отнестись более внимательно. Из-за отсутствия возможности завести кошелек в украинской гривне, пополнение будет произведено с помощью долларового кошелька. Соответственно он должен быть предварительно создан и на нем должны быть деньги в долларовом эквиваленте. Лимит идентичен предыдущему методу и составляет от 50 до 30 000 гривен.

Пополнение в «Мостбет» через WebMoney

Система сама произведет конвертацию заказанной суммы. Останется авторизоваться и подтвердить транзакцию с помощью электронного кошелька WebMoney. За 50 грн придется отдать 3.60 доллара. Сюда уже включены все комиссии за обмен и перевод денег.

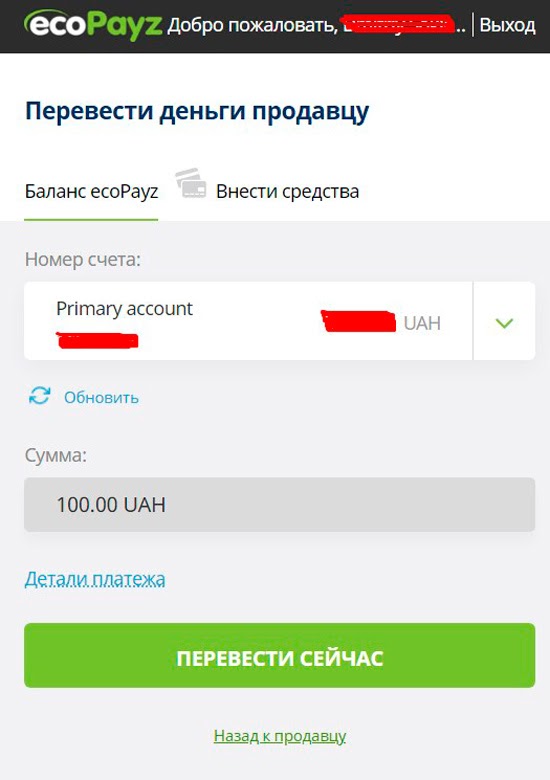

EcoPayz

Депозит с помощью EcoPayz идентичен пополнению через WebMoney. Игрока перекидывает на электронный кошелек, где нужно подтвердить сделку. При необходимости можно изменить сумму платежа уже в процессе оплаты.

Пополнение через EcoPayz

Преимущество EcoPayz перед WebMoney в том, что здесь доступен кошелек в гривнах. Это означает, что дополнительных взысканий за конвертацию не будет.

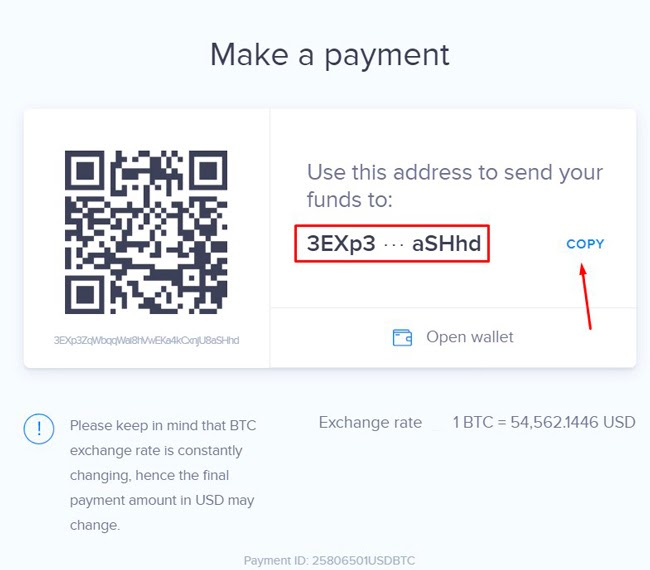

Криптовалюта

Самый необычный и новый способ это криптовалюта. Букмекер предлагает сразу 4 варианта (Bitcoin, litecoin, ethereum, ripple). Это все разные способы депозита, но имеющие один и тот же алгоритм действий:

- Скопировать номер персонального адреса;

- При необходимости купить криптовалюту на одном из интернет-обменников;

- Подтвердить оплату между личным кошельком и счетом на сайте «Мостбет».

Пополнение счет в Mostbet криптовалютой

Данный способ оплаты не самый тривиальный и точно не быстрый. У 99% пользователей нет своей криптовалюты, а для ее приобретения придется потратить много времени на покупку, и не факт, что это будет выгодная сделка. Но есть и заметные преимущества криптовалюты, это ее полная анонимность.

Советы от Herobet

В «Мостбет» пополнить счет не составит никакого труда. Самым удобным и универсальным способом считается банковская карта. Но стоит понимать, что вывести деньги можно лишь тем способом, которым изначально заводили. В этом случае карты Visa и MasterCard подходят не лучшим образом. Во-первых, время вывода может занять до 3-х рабочих дней. Во-вторых, у банка могут появиться вопросы относительно происхождения денежных средств.

В скорости переводов и анонимности ничто не сравниться с электронными кошельками и криптовалютой. Но стоит быть готовым к тому, что помимо стандартной комиссии, еще придется уплатить дополнительные проценты за конвертацию и переводы внутри кошелька/обменника/биржи.

Каждый игрок выбирает для себя максимально удобный способ, но важно запомнить, что путь ввода и вывода денег на сайте «Мостбет» будет один.